FUNAS Rock Wool Board — High-Performance Thermal Insulation

Product Overview

FUNAS Rock Wool Board is a high-performance insulation panel designed to deliver reliable thermal protection, sound absorption, and fire safety across industrial and commercial applications. Made by FUNAS, an integrated science & technology company founded in 2011, this board benefits from decade-long expertise in insulation materials and a 10,000 m² Guangzhou storage center to ensure fast supply.

Key Benefits

- Excellent thermal insulation — reduces heat loss and saves energy costs.

- Fire resistant and non-combustible — enhances building and equipment fire safety.

- Good sound absorption — improves acoustic comfort in rooms and plants.

- Durable and stable — resists deformation, retains performance over time.

- Low moisture uptake — maintains insulation properties in humid conditions.

- Easy to cut and install — fits common construction and HVAC workflows.

Applications

FUNAS Rock Wool Board is widely used in petroleum and petrochemical plants, power generation, metallurgy, polysilicon production, coal chemical facilities, central air conditioning systems, refrigeration, and commercial buildings. Its combination of thermal efficiency and fire safety makes it ideal for ducts, pipe cladding, walls, ceilings, and equipment insulation.

Certifications & Customization

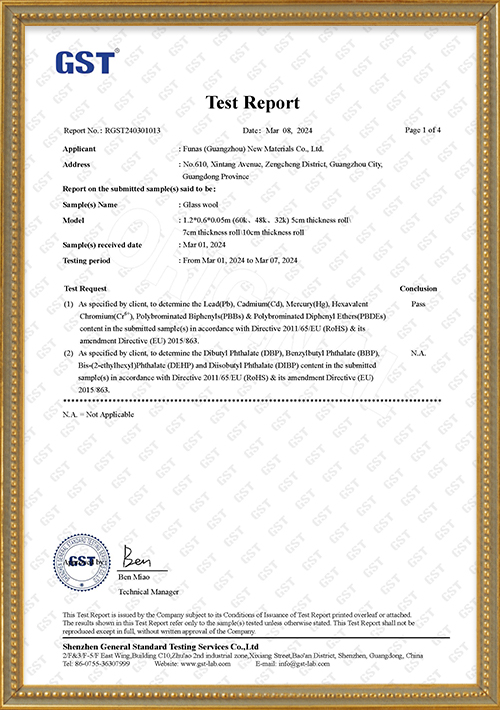

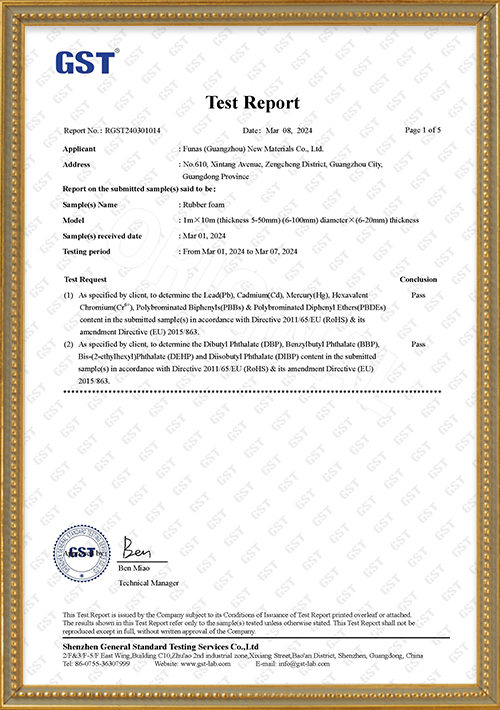

FUNAS products meet strict quality and environmental standards. The company has obtained CCC and CQC compulsory certifications and holds CE, ROHS, CPR, UL, and FM approvals. FUNAS is ISO 9001 and ISO 14001 certified. We offer brand customization to meet your specifications and seamless supply from our Guangzhou warehousing center.

Why Choose FUNAS Rock Wool Board?

With a strong R&D and production background, proven certifications, and flexible customization, FUNAS delivers insulation solutions that balance safety, performance, and cost. Whether upgrading an industrial plant or insulating a commercial HVAC system, FUNAS Rock Wool Board provides dependable results and fast delivery.

Visit https://www.funasinsulations.com/ to learn more or contact our sales team for samples, specifications, and tailored solutions.

Advantages

Flexible production plan

We can flexibly arrange production plans according to your needs, and the delivery time is within 7–30 days to ensure that your market needs can be met in a timely manner.

Professional consulting team

We have a highly professional team that can provide customers with comprehensive and in-depth consulting services on insulation material.

Large-scale production capacity

Our large-scale production capacity ensures that your orders can be delivered on time; whether it is a minimum order of 500 pieces or N+ customized services, we can meet your needs with top-quality China heat insulation solutions.

Product customization capabilities

The difference between us and our competitors lies in our heat resistant insulation material product customization capabilities, covering size, specifications, color, packaging and other aspects to meet customers' personalized needs.

Qualification Certificate

Glass wool CE test report

Test report - Ongo resin 36

Rubber and plastic CE test report

Frequently Asked Questions

What is the typical delivery time for custom orders?

Our daily production capacity is 800 cubic meters. Delivery time varies depending on the complexity of the insulation material wholesale order, but we can deliver large quantities of customized products within 4-6 weeks after the approval date, and small quantities can be delivered within 15 days.

What is your shipping and delivery process like?

We offer reliable logistics services for insulation material wholesale, both domestically and internationally. Our team ensures secure packaging, timely shipping, and real-time tracking so that your order reaches you in perfect condition and on schedule.

What types of rubber foam insulation products do you offer?

We offer a wide range of rubber foam insulation products, including custom shapes and sizes, thermal and acoustic insulation solutions, and options with specialized coatings such as flame retardancy and water resistance. Our products are suitable for applications in HVAC, automotive, construction, and more.

How does your technical support work?

Our technical support team is available to guide you through every stage of your project—from product selection and design to installation. We provide expert consultation to ensure that you get the best insulation solution for your needs and can assist with troubleshooting if needed.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

Wholesale Perfect Fire Resistant Performance High Strength Acoustic Mineral Wool Insulation Rock Wool Board Panel Plain Slab

Rock wool board, that is, a kind of exterior insulation material. When the market share of 90% of the organic thermal insulation materials in the stagnant wait-and-see, as a fire rating of A-class exterior insulation inorganic material rock wool, has ushered in an unprecedented market opportunity.