2026 Guide to Thermal Insulation Material Manufacturers

Explore our 2026 guide to thermal insulation material manufacturers and learn how to stay ahead in a changing global market.

- Market Snapshot & Outlook for 2026

- Key Growth Factors

- Key Drivers & Challenges for Manufacturers in 2026

- Drivers

- Challenges

- Segments Worth Watching in 2026

- Growth Strategies for Thermal Insulation Material Manufacturers in 2026

- Broaden product range and tailor to application :

- Strengthen certifications & specification readiness :

- Target B2B OEM/ODM partnerships and customised supply chains:

- Emphasise sustainability & dual-function performance:

- Optimize logistics and regional warehousing:

- Support installation and performance through services:

- Use digital manufacturing and traceability:

- Recommendations for 2026

- Focus on high-growth segments and markets:

- Allocate R&D towards dual-function and niche markets:

- Strengthen B2B supply chain and branding:

- Update logistics and inventory strategy:

- Enhance installation support and training:

- Monitor raw-material pricing and diversify supply:

- Promote certifications and audit trails:

- FAQs about Thermal Insulation Material Manufacturers

- 1. How do I choose among thermal insulation material manufacturers?

- 2. What is the best thermal insulation material?

- 3.How are soundproofing insulation materials related to thermal insulation?

- 4. What should I consider when sourcing pipe insulation material or underground pipe insulation material?

- 5.Why is 2026 an important year for thermal insulation material manufacturers?

- Conclusion

Market Snapshot & Outlook for 2026

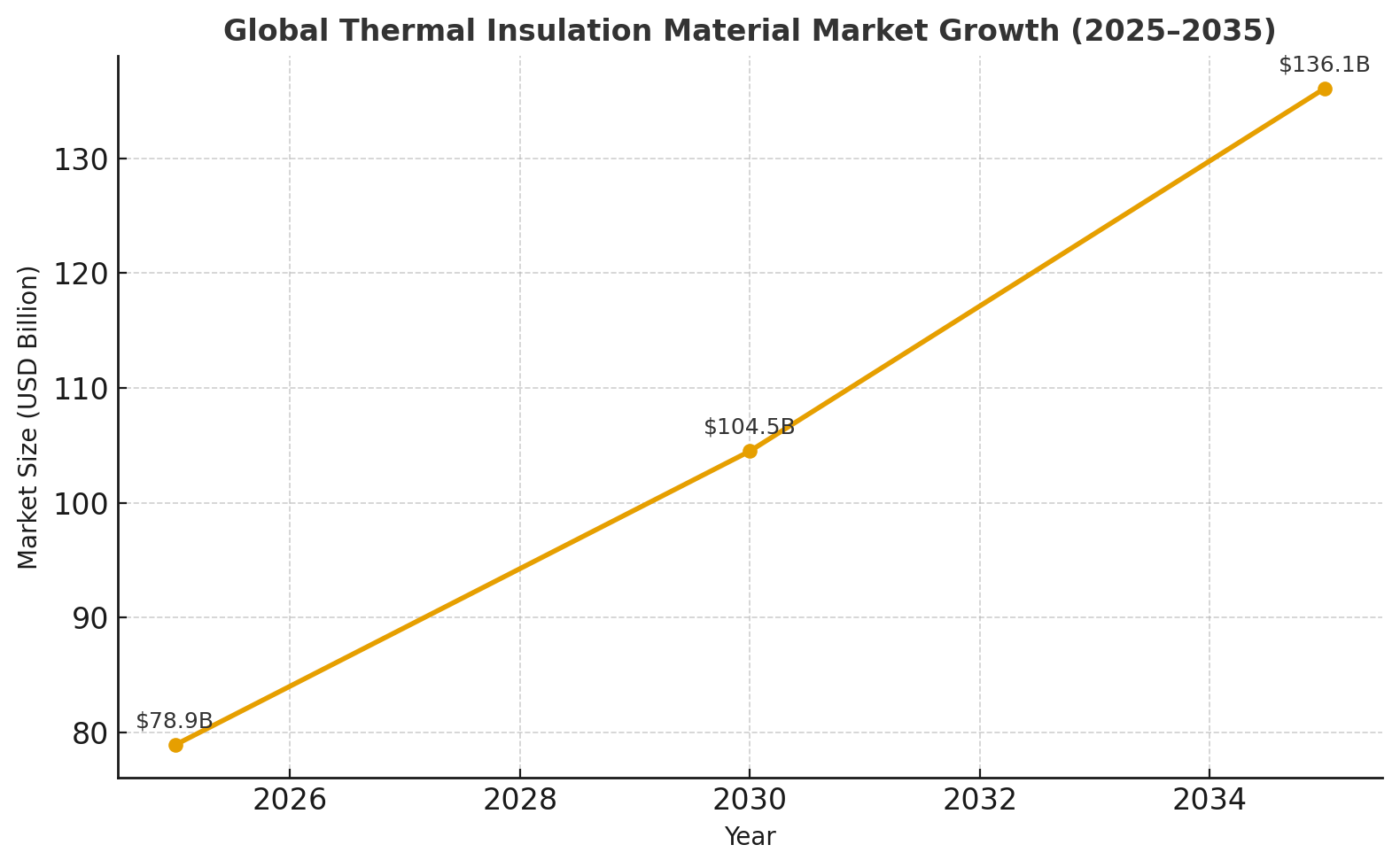

The global thermal insulation material market is doing well. This includes insulation used for thermal control in buildings, industry and refrigeration. One of the main estimates puts its value at USD 78.9 billion in 2025, with a prediction it'll hit USD 136.1 billion by 2035, which works out to a CAGR of around 5.6% for 2025 to 2035. (Future Market Insights)Another source says the 2023 market was USD 71.7 billion, and they're predicting it'll reach USD 96.0 billion by 2028 (about 6.0% CAGR) for the thermal insulation segment alone. (Data Source:MarketsandMarkets)

Looking at 2026 specifically, this means the market is already growing. By 2026, manufacturers of thermal insulation material suppliers will face an environment of accelerating demand, particularly in retrofit building projects, industrial process insulation (e.g. in petrochemical, power, polysilicon) and refrigeration/cold-chain installations.

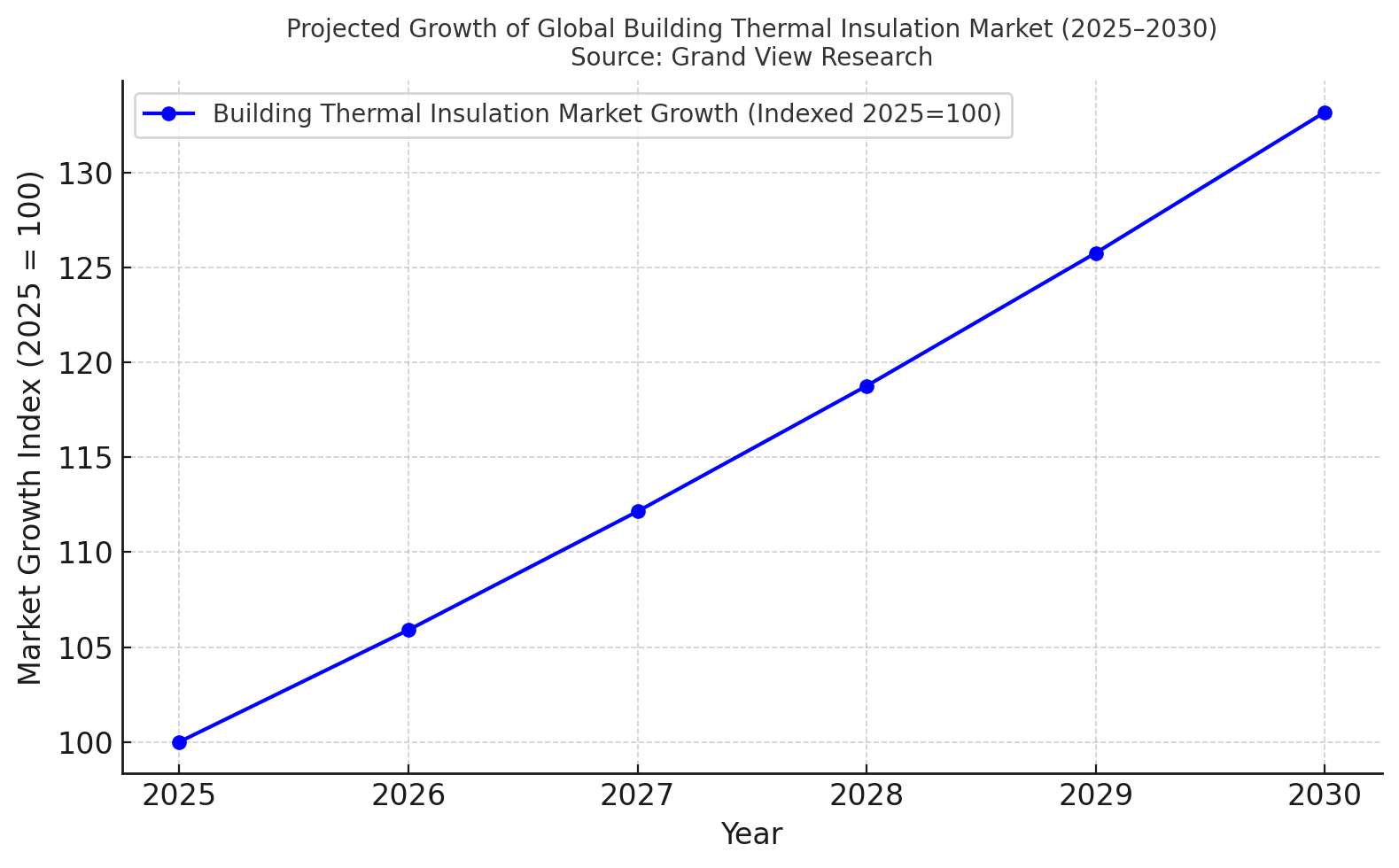

For example, in the building thermal insulation subset, the market was estimated at USD 26.87 billion in 2024 and projected to reach USD 37.76 billion in 2030, at a CAGR of 5.9% from 2025-2030. (Data Source:Grand View Research)

So, for a manufacturer like FUNAS offering insulation material for industrial piping, HVAC, cold-chain and building applications, 2026 is a great time to get products ready, expand into new markets and make the brand stand out.

Key Growth Factors

Here are the major growth factors for thermal insulation material manufacturers, with brief descriptions:

| Growth Factor | Description |

|---|---|

| Stricter energy efficiency and building codes | Many regions are tightening thermal-performance and R-value requirements in buildings, driving demand for higher-performance insulation. |

| Expansion of cold-chain refrigeration and HVAC upgrades | Growth in e-commerce, pharmaceuticals and food logistics increases demand for pipe insulation material, aircon insulation material and refrigeration insulation solutions. |

| Urbanization and industrial infrastructure development (especially in APAC) | Rapid growth in Asia-Pacific (China, India, Southeast Asia) means more new construction, industrial plants and retrofits — creating demand for insulation material suppliers. |

| Acoustic/soundproofing and multifunction insulation needs | Beyond thermal control, soundproofing insulation material, the best acoustic insulation material and car sound insulation material are seeing rising interest, so manufacturers can cross-leverage capabilities. |

| Fire safety, sustainability and regulatory compliance pressure | Fire‐proof insulation material and environmentally friendly options are increasingly specified; manufacturers with certifications and eco-grades gain advantage. |

| Raw material and cost dynamics creating supply-chain opportunity | While volatility may be a challenge, manufacturers that control raw materials or optimise logistics (such as having large storage centres like FUNAS’s 10,000 m² warehouse) can capture margin and service advantage. |

Key Drivers & Challenges for Manufacturers in 2026

Drivers

| Driver | Description |

|---|---|

| Regulatory push for energy savings | Governments and codes increasingly require improved thermal performance, which translates into more demand for thermal insulation materials. For example, the global building thermal insulation market is projected to grow at ~5.9% CAGR from 2025-2030. (Data Source:Grand View Research) |

| Growth in industrial and process insulation | The industrial insulation market is projected to grow (e.g., industrial insulation valued at USD 8.21 billion in 2022 and expected to rise to ~USD 12.10 billion by 2030 at ~5% CAGR). (Data Source:Grand View Research) |

| Need for acoustic and combined performance insulation | The acoustic insulation market is estimated at USD 14.75 billion in 2023, projected to grow (CAGR ~4.3%) to reach USD 21.03 billion by 2030. (Data Source:Grand View Research) |

Challenges

| Challenge | Description |

|---|---|

| Raw material price volatility & cost pressure | Insulation manufacturers must manage feedstock cost changes and processing cost inflation, which can squeeze margins. |

| Certification, fire-safety and performance complexity | Different regions demand fire-ratings, environmental certifications (e.g., CE, UL, ROHS) and installation quality; manufacturers must invest accordingly (FUNAS already holds CCC, CQC, CE, ROHS, CPR, UL, FM, ISO 9001, ISO 14001). |

| Installation quality and skilled labor constraints | Even the best insulation material under-performs if installed poorly; manufacturers must support training or provide prefabricated systems. |

| Sustainability demands and technology transition | There is increasing demand for low-VOC, recyclable, eco-friendly insulation; companies must invest in new formulations and manufacturing processes. |

| Competitive pressure and differentiation | As more players enter, differentiation via product performance (e.g., high heat insulation material, flexible insulation material) and service becomes key. |

Segments Worth Watching in 2026

Here are key segments where thermal insulation material manufacturers should direct focus:

| Segment | Why it matters in 2026 | Opportunities for manufacturers (e.g., FUNAS) |

|---|---|---|

|

Rubber Foam & Plastic Insulation |

Excellent for pipe insulation material, aircon insulation material, hot water pipe insulation material in HVAC/refrigeration. | Provide flexible insulation material for HVAC and refrigeration systems; customise diameters; support B2B OEMs. |

|

Rock Wool / Mineral Wool |

Fireproof insulation material and high heat insulation material; widely used in industrial plants (petrochemical, power, polysilicon). | Offer certified fire-resistant insulation for petrochemical/metallurgy industries; use rock wool boards/rolls. |

|

Glass Wool |

Best building insulation material for walls and ceilings; good acoustic and thermal performance. | Provide glass wool panels and rolls; tap into retrofit/green-building demand; highlight best insulation material credentials. |

|

Acoustic / Soundproof insulation (soundproofing insulation material) |

With growing urbanisation and sound-control regulations, acoustic insulation is a companion opportunity. | Cross-sell best sound insulation material, car sound insulation material, insulation material for lunch bags (niche) to expand scope. |

|

High-performance & eco-friendly products |

As space gets limited and sustainability mandates increase, premium high-R materials and recyclable options matter. | Develop thermal insulation blanket material, insulation material for ovens, underground pipe insulation material and other niche high-performance applications. |

Growth Strategies for Thermal Insulation Material Manufacturers in 2026

-

Broaden product range and tailor to application :

-

Keep a wide range of products on offer (like rubber and plastic insulation, rock wool, and glass wool) so you can meet the needs of HVAC/Refrigeration (pipe and air conditioning insulation), building (top home and attic insulation), and industrial (fireproof and high heat insulation) markets.

-

Strengthen certifications & specification readiness :

-

Make sure products have the right certifications (CE, UL, FM, ROHS, CPR) and meet building/industrial codes for thermal, acoustic and fire performance. FUNAS already holds these certifications, giving it a competitive edge

-

Target B2B OEM/ODM partnerships and customised supply chains:

-

We offer thermal insulation material suppliers and distributors branding, packaging and logistics services to suit their needs, and enable bulk supply to HVAC OEMs, refrigeration system integrators, and construction contractors.

-

Emphasise sustainability & dual-function performance:

-

Come up with insulation products that keep things warm and quiet (like soundproofing insulation material or the best acoustic insulation material), and make sure they're good for the environment (like insulation material for lunch bags, a niche or low-VOC glass wool).

-

Optimize logistics and regional warehousing:

-

As we expand into new markets, it's important to keep regional storage on hand, like FUNAS's massive 10,000 m² centre in Guangzhou, to make sure we can get products to the Asia-Pacific, Middle East, Europe and North America regions quickly.

-

Support installation and performance through services:

-

We can provide training for installers, certified installer networks, specification guides and support for decisions about the best sound and thermal insulation materials.

-

Use digital manufacturing and traceability:

-

Get on board with Industry 4.0 tools for quality control and supply-chain visibility, so you can keep your customers happy by making sure your products are reliable, and that you've got all the warranty claims and performance data you need for high-end segments (like auto, wire and oven insulation material).

Recommendations for 2026

-

Focus on high-growth segments and markets:

-

Focus on new construction and retrofitting in Asia-Pacific, and industrial piping/plant insulation in petrochemical/metallurgy sectors where there's a strong demand for pipe insulation material, underground pipe insulation material and high heat insulation material.

-

Allocate R&D towards dual-function and niche markets:

-

Invest in products that offer thermal and sound insulation (like soundproofing insulation material and car sound insulation material) and eco-friendly options to win projects that focus on sustainability.

-

Strengthen B2B supply chain and branding:

-

Come up with clear value propositions for suppliers and distributors of thermal insulation materials, and promote FUNAS's customisation services and global certifications to build trust.

-

Update logistics and inventory strategy:

-

Use your storage centre and logistics system to reduce lead times and support large-volume B2B orders for HVAC, construction and refrigeration.

-

Enhance installation support and training:

-

Give installers and end-users clear guidance on picking the best building insulation material, the best wall insulation material or the best insulation material for lunch bags (niche) to make sure the product performs well and customers are happy.

-

Monitor raw-material pricing and diversify supply:

-

Try to protect your business against changes in the prices of the things you need to make your products, make sure you've got more than one way to get your raw materials, and keep an eye on how much things are costing you so you can make a profit on foam, mineral wool and glass wool products.

-

Promote certifications and audit trails:

-

Use your qualifications (ISO 9001, ISO 14001, UL, CE) to market to global clients, and make sure B2B buyers and project specifiers can trace everything.

FAQs about Thermal Insulation Material Manufacturers

1. How do I choose among thermal insulation material manufacturers?

When it comes to the manufacturer, it's worth checking out their product range (like rubber and plastic insulation, rock wool, and glass wool), performance certificates (like fire, thermal R-value, and acoustic), their ability to supply to other businesses (customisation, OEM/ODM), and their global logistics support. FUNAS, for example, offers all of these things.

2. What is the best thermal insulation material?

There isn't one solution that works every time. It depends on the application: for HVAC pipe insulation, closed-cell rubber or plastic insulation is ideal; for fire-safe industrial plant, rock wool is preferred; for building walls/ceilings, glass wool may be most cost-effective. As a manufacturer, it's important to offer a range of choices and help your clients make the right choice.

3.How are soundproofing insulation materials related to thermal insulation?

Many insulation materials provide both thermal and acoustic insulation (e.g., glass wool, rock wool). So manufacturers who make both thermal and soundproofing insulation can meet two needs at once — offering "best acoustic insulation material" as well as "best insulation material" for thermal control.

4. What should I consider when sourcing pipe insulation material or underground pipe insulation material?

The most important things to think about are the temperature range (the difference between the hot water pipe insulation material and the cold refrigerant lines), how well they can resist moisture and vapour, and how well they can resist fire (especially for industrial pipelines). It's also important to think about how easy they are to install and maintain. Manufacturers like FUNAS that offer rubber/plastic insulation, rock wool for high heat, and custom solutions are well placed.

5.Why is 2026 an important year for thermal insulation material manufacturers?

As regulations on energy efficiency, fire safety and sustainability are being introduced all over the world, there's more and more demand for retrofit construction, cold-chain infrastructure and dual-function insulation (thermal + acoustic). 2026 is a big year for us – it's when we'll really start to see manufacturers who are prepared (in terms of products, certification and logistics) start to grow.

Conclusion

2026 is going to be a big year for companies that make thermal insulation materials. The market is huge and growing fast (for example, the global thermal insulation material market was worth USD 78.9 billion in 2025 and is expected to be worth USD 136.1 billion by 2035) (Future Market Insights). The companies that make all sorts of materials (rubber and plastic, rock wool, glass wool), get great certifications, build partnerships with other companies and support sound and acoustic performance as well as thermal performance, and optimise logistics, will be the ones to watch.

FUNAS has got its ducks in a row for 2026 and the future, with its full product range, global certification credentials, custom-brand services and strong storage/logistics infrastructure. If you focus on segmentation (HVAC, refrigeration, building, industrial), emphasise dual performance (thermal + acoustic), pursue sustainability and installation support, you'll be all set to capture the next wave of industry growth.

Polyurethane Foam 2026: Guide to HFO Compliance & Performance

The Ultimate 2026 Rock Wool Bible: Why It Beats Fiberglass Every Single Time [Full Comparison]

Why Glass Wool is the Secret to a 40% Lower Energy Bill: An Expert Deep Dive

2026 Rubber Sheet Guide: Types, Properties, and Applications Explained

service

Are your rubber foam products environmentally friendly?

Yes, our insulation products are designed with sustainability in mind. They help reduce energy consumption by minimizing heat loss and gain, and they are made from durable materials that have a long life cycle, reducing the need for frequent replacement.

FAQ

Can your insulation products be customized?

Yes, we offer customized solutions for insulation material wholesale to meet the specifications of your project, including custom specifications, sizes, foils and adhesives, colors, etc.

How do I choose the right insulation for my project?

Our team can help you choose the best material for heat insulation based on your specific needs, such as thermal resistance, acoustic properties, and environmental conditions.

What types of rubber foam insulation do you offer?

We offer a wide range of rubber foam insulation with different thicknesses and specifications. Thermal insulation material manufacturer FUNAS sleeves and sheets are suitable for different application scenarios.

You might also like

138°High-temperature universal adhesive

This product has passed the EU REACH non-toxic standard and ROHS non-toxic standard. (This product is a yellow liquid).

Anggu 138°high temperature universal glue is a high-end product, with high viscosity, slow drying, curing of the adhesive layer, and a maximum resistance to continuous temperature of 138℃.

Special adhesive for insulation nail

This product has passed the EU REACH non-toxic standard and ROHS non-toxic standard. (This product is a yellow liquid).

Anggu insulation nail special adhesive is a adhesive with high viscosity, slow drying, aging resistance, high strength, and excellent brushing performance; The special adhesive for insulation nails has a slow drying speed and strong adhesion to the iron sheet. It can be flexibly moved during construction, and has a strong bonding force after curing, low odor.and is non-toxic.

Wholesale Perfect Fire Resistant Performance High Strength Acoustic Mineral Wool Insulation Rock Wool Roll Panel Plain Slab

Rock wool, that is, a kind of exterior insulation material. When the market share of 90% of the organic thermal insulation materials in the stagnant wait-and-see, as a fire rating of A- class exterior insulation inorganic material rock wool has ushered in an unprecedented market opportunity.

Wholesale Rock Wool Mineral Wool Board Panel Sheet

High-performance rock wool board for superior thermal and acoustic insulation. A reliable choice for building projects.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.