A professional procurement process must include a review of Technical Data Sheets (TDS), which provide critical information regarding product specifications, performance, and compliance. By reviewing TDS, procurement teams can ensure the materials meet the required quality standards. Additionally, exploring the Top 10 Global Polyurethane Foam Manufacturers helps identify suppliers who consistently deliver reliable, high-quality products that adhere to international safety and environmental standards.

Polyurethane Foam 2026: Guide to HFO Compliance & Performance

Don't let 2026 HFC bans disrupt your supply. High-quality polyurethane foam delivers elite insulation, cushioning, and sealing. Secure your HFO-compliant roadmap and technical edge today.

- Introduction

- The Regulatory Transition to HFO-Blown Foam Polyurethane

- Why High-Quality Polyurethane Foam Offers Excellent Insulation, Cushioning, and Sealing Properties

- Maximizing Thermal Efficiency with Polyurethane Foam Insulation Boards

- Versatility of Flexible Polyurethane Foam in Industrial Sheets

- Structural Integrity and Moisture Resistance of Rigid Polyurethane Foam

- Impact of Density on the Performance of High Density Polyurethane Foam

- Critical Compliance and Safety Standards for Manufacturers

- Customizing Polyurethane Foam Sheet and Board Solutions

- Sustainable Innovation and the Future of Circularity

- Conclusion

- FAQs: Frequently Asked Questions for Material Buyers

- Is HFC-based foam still legal for my project?

- What is the difference between open cell and closed cell polyurethane foam?

- Why is density a critical factor for polyurethane foam board?

- Can high density polyurethane foam be recycled?

- How do HFO-blown foams compare in cost?

- References

Introduction

As a marketing director with over a decade in the synthetic materials industry, I can tell you that the conversation around polyurethane foam has fundamentally changed. We are no longer in an era where procurement is driven by price alone. In 2026, the focus has shifted entirely toward technical compliance, material longevity, and the global transition to sustainable chemistry.

For project managers and industrial designers, the shift from Hydrofluorocarbons (HFCs) to Hydrofluoroolefins (HFOs) is the single biggest supply chain challenge of the decade. This guide explores how to navigate these changes while ensuring that your polyurethane foam board and sheet selections deliver the peak performance your applications demand.

The Regulatory Transition to HFO-Blown Foam Polyurethane

The most critical factor in sourcing material today is understanding the regulatory timeline. As of January 1, 2025, a comprehensive ban on the manufacture of polyurethane foam systems using high Global Warming Potential (GWP) HFCs took effect in many global markets, including the United States . This includes rigid boardstock, flexible systems, and integral skin products .

We have now entered the generation of HFO blowing agents. While older HFCs had a GWP often exceeding 1,000, next-generation HFOs—such as HFO-1233zd(E)—feature a GWP of less than 1.1 When vetting polyurethane foam manufacturers, the priority is verifying that their board and sheet products are HFO-compliant. This ensures your projects meet the latest green building codes and avoids the risk of using "legacy" materials that face an imminent sale-and-installation cutoff by 2028 .

Why High-Quality Polyurethane Foam Offers Excellent Insulation, Cushioning, and Sealing Properties

The versatility of this polymer is unmatched because its cellular structure can be precisely engineered. In 2026, high-quality formulations ensure that a single polyurethane foam sheet or board can perform three critical functions without compromise:

-

Insulation: The captive HFO gases within the cell matrix create a thermal barrier that is nearly twice as effective as traditional mineral wool .

-

Cushioning: In its flexible form, the material’s energy absorption protects delicate equipment and provides ergonomic support in furniture and medical applications.

-

Sealing: Closed cell polyurethane foam boards create an impermeable barrier against air and water vapor, which is essential for preserving the structural integrity of building envelopes and refrigerated containers .

Choosing a premium grade ensures these properties remain stable for 20 to 30 years of service life.

Maximizing Thermal Efficiency with Polyurethane Foam Insulation Boards

Thermal resistance, measured as R-value, is the primary reason engineers specify polyurethane foam insulation. One of the "hidden" benefits of the HFO transition is that it has actually improved thermal performance. Research indicates that HFO-blown systems provide a 10% increase in R-value compared to older HFC formulations.

A high-performance rigid polyurethane foam board can achieve an R-value of 6.2 to 7.0 per inch . This is significantly higher than expanded polystyrene (EPS) or fiberglass, allowing designers to achieve the same insulation levels with much thinner wall profiles . This space-saving capability is a game-changer in high-density urban construction and transport refrigeration where every cubic inch matters.

Versatility of Flexible Polyurethane Foam in Industrial Sheets

While rigid boards handle the structural load, flexible polyurethane foam remains the gold standard for protection and comfort. In 2026, we see a growing demand for high-resilience sheets used in medical wound care and high-end cushioning .

When purchasing a polyurethane foam sheet, the key metric is "compression set"—the material's ability to rebound to its original thickness after being loaded . High-quality sheets utilize a "high sag factor" chemistry, which provides initial softness but increasing support as more pressure is applied. This is critical for industrial ergonomic mats and medical patient positioning, where long-term durability is a non-negotiable requirement.

Structural Integrity and Moisture Resistance of Rigid Polyurethane Foam

For heavy-duty applications, a polyurethane foam board is often used as a structural core. In cold chain logistics and roofing, its high compressive strength (typically 15 to 60 psi) allows it to handle significant weight without deforming .

Because closed cell polyurethane foam has a closed-cell rate of over 90%, it acts as an effective secondary water barrier . Unlike open-cell materials that can act like a sponge, these rigid boards absorb less than 3% water by volume. This prevents the growth of mold and fungi, making it the safest choice for high-humidity environments like basements or industrial kitchens .

Impact of Density on the Performance of High Density Polyurethane Foam

In 2026, many of our high-intent inquiries focus on high density polyurethane foam. Density, measured in pounds per cubic foot (PCF), is the single best predictor of foam durability and mechanical strength.

| Density Grade | Typical PCF | Best Industrial Application |

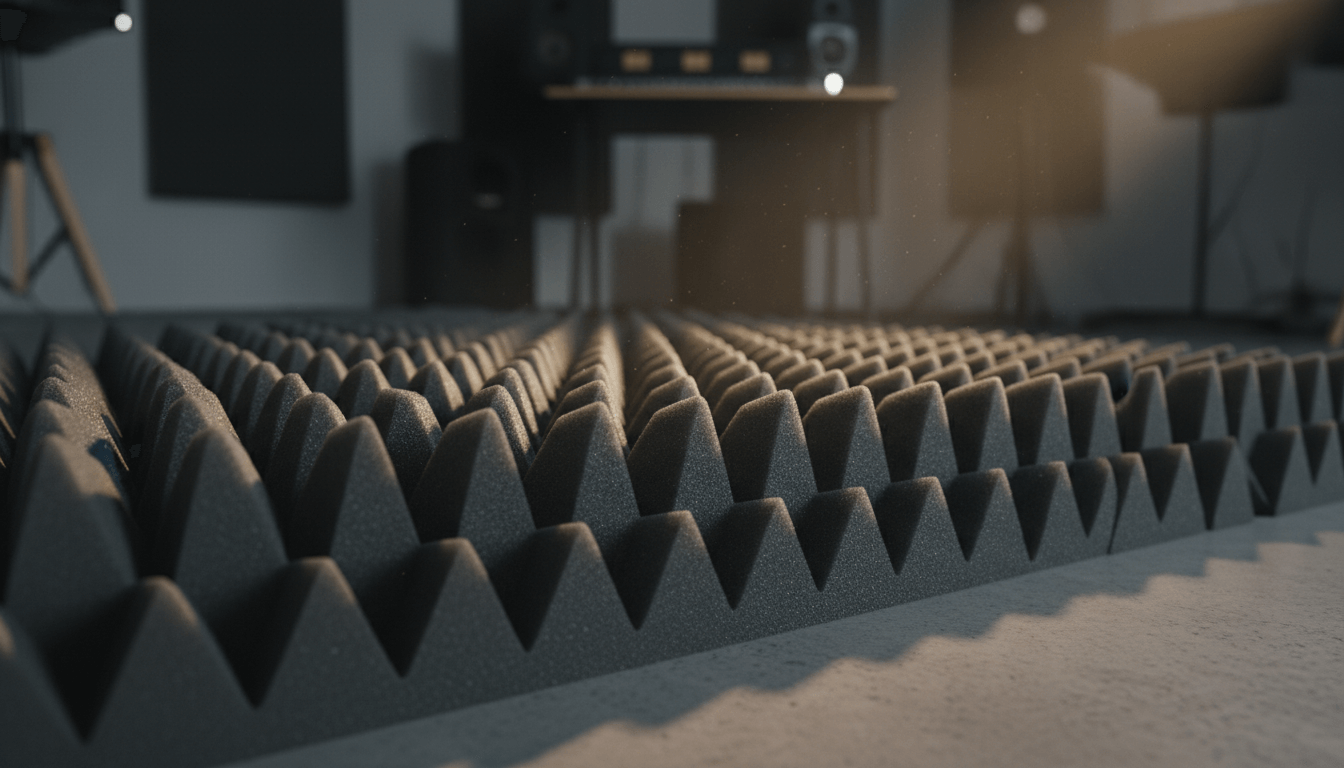

| Low Density | 0.5 - 1.5 | Soundproofing and light packaging |

| Medium Density | 1.8 - 2.5 | General-purpose insulation boards |

| High Density Polyurethane Foam | 3.0 - 10.0+ | Structural panels, modeling, and seals |

Higher density materials use more polymer in the cell walls, making the foam more resistant to "thermal drift" (the gradual loss of R-value) and mechanical breakdown . For sealing gaskets or structural cores, specifying a high-density polyurethane foam sheet is essential to ensure long-term performance under pressure.

Critical Compliance and Safety Standards for Manufacturers

Fire Safety (ASTM E84): Materials should achieve a Class A or Class 1 rating, indicating low flame spread and low smoke production .

-

Low VOC Emissions: To maintain indoor air quality, look for CertiPUR-US or Greenguard Gold certifications, which verify that the foam is free from harmful chemicals like methylene chloride .

-

Shelf Life Stability: HFO-blown systems are chemically sensitive. Confirm that your supplier manages their B-side (resin) formulations to ensure a reliable 6-month shelf life under controlled storage conditions .

Customizing Polyurethane Foam Sheet and Board Solutions

Standard sizes rarely meet the needs of specialized manufacturing. Top suppliers now utilize precision vertical and horizontal cutting to deliver polyurethane foam sheets and boards tailored to exact specifications .

Whether you need a polyurethane foam mat with specific anti-static properties for electronics or custom-molded parts for medical instruments, "dimensional stability" is key. High-quality material will not warp or twist when exposed to temperature extremes, which reduces waste during the final assembly process. By sourcing custom-cut polyurethane foam sheets, manufacturers can reduce material scrap rates by up to 20%. Understanding the polyurethane foam manufacturing process is crucial for achieving the highest precision and optimizing material usage throughout production.

Sustainable Innovation and the Future of Circularity

Looking toward 2030, the industry is moving beyond "low GWP" and toward full circularity. Innovations in bio-based polyols—derived from vegetable oils and agricultural waste—now allow for polyurethane foam with a 15% lower carbon footprint .

Furthermore, chemical recycling is now making it possible to break down an old polyurethane foam board into its original monomers to be used as virgin-quality raw material again . When inquiring about foam polyurethane, ask your supplier about their "mass balance" approach to sustainable content. This not only supports global climate goals but also enhances your company's ESG profile for institutional contracts .

Conclusion

In the world of synthetic polymers, quality is not a luxury—it is a requirement for safety and compliance. Choosing a non-compliant or low-density material might offer a small upfront saving, but it risks catastrophic failure in thermal performance and regulatory audits.

Investing in high-quality polyurethane foam—whether it’s a rigid polyurethane foam board, a durable polyurethane foam mat, or versatile polyurethane foam sheets—is an investment in the long-term integrity of your product. By focusing on HFO-compliant technology and high-density performance, you ensure that your projects benefit from the best insulation, cushioning, and sealing properties available in 2026.

FAQs: Frequently Asked Questions for Material Buyers

Is HFC-based foam still legal for my project?

As of January 1, 2025, the manufacture of HFC-blown closed-cell foams is illegal in the U.S. and many other regions . While there is a "sell-through" provision for existing stock until 2028, most modern project specs now mandate the use of zero-GWP HFO systems to ensure future compliance and insurance eligibility.

What is the difference between open cell and closed cell polyurethane foam?

Closed cell polyurethane foam has a dense, sealed structure that provides a high R-value and acts as a moisture barrier . Open cell polyurethane foam is lighter and more flexible, making it excellent for sound dampening and cushioning, though it has a lower insulation value and is permeable to moisture .

Why is density a critical factor for polyurethane foam board?

Density determines the material's weight-bearing capacity and its resistance to R-value degradation over time . High density polyurethane foam is mandatory for structural applications and heavy-duty insulation where the board must resist compression and moisture intrusion .

Can high density polyurethane foam be recycled?

Yes. Currently, mechanical recycling turns scrap foam into products like polyurethane foam mats or carpet padding . Advanced chemical recycling technologies are also being deployed to recover raw polyols from end-of-life boards and mattresses .

How do HFO-blown foams compare in cost?

HFO blowing agents are more expensive to produce than older HFCs, which can lead to a 10-15% increase in material costs . However, this is typically offset by the 10% improvement in thermal performance and the avoidance of regulatory non-compliance fines .

References

Fiberglass vs. Rockwool: Which Soundproofing Insulation Material Wins for Acoustic Control?

Sound Insulation Foam vs. Acoustic Panels: Which One Actually Stops Noise? (2026 Guide)

7 Dangerous Mistakes to Avoid When Selecting insulating materials for Your Car (2026 Guide)

The Ultimate 2026 Rock Wool Bible: Why It Beats Fiberglass Every Single Time [Full Comparison]

service

What types of rubber foam insulation products do you offer?

We offer a wide range of rubber foam insulation products, including custom shapes and sizes, thermal and acoustic insulation solutions, and options with specialized coatings such as flame retardancy and water resistance. Our products are suitable for applications in HVAC, automotive, construction, and more.

Are your rubber foam products environmentally friendly?

Yes, our insulation products are designed with sustainability in mind. They help reduce energy consumption by minimizing heat loss and gain, and they are made from durable materials that have a long life cycle, reducing the need for frequent replacement.

How does your technical support work?

Our technical support team is available to guide you through every stage of your project—from product selection and design to installation. We provide expert consultation to ensure that you get the best insulation solution for your needs and can assist with troubleshooting if needed.

FAQ

What types of rubber foam insulation do you offer?

We offer a wide range of rubber foam insulation with different thicknesses and specifications. Thermal insulation material manufacturer FUNAS sleeves and sheets are suitable for different application scenarios.

You might also like

138°High-temperature universal adhesive

This product has passed the EU REACH non-toxic standard and ROHS non-toxic standard. (This product is a yellow liquid).

Anggu 138°high temperature universal glue is a high-end product, with high viscosity, slow drying, curing of the adhesive layer, and a maximum resistance to continuous temperature of 138℃.

Blue Rubber-plastic Tube Rubber foam pipe wholesale

Wholesale Rock Wool Mineral Wool Roll Blanket

Durable rock wool roll with outstanding fire resistance and insulation properties. Ideal for industrial and construction applications.

Wholesale Roof And Wall Thermal Heat Insulation 50mm Thickness Aluminum Foil Fiberglass Insulation Panel Board Glass Wool Price

Glass wool is the molten glass fiber, the formation of cotton-like material, chemical composition belongs to the glass category, is a kind of inorganic fiber. With good molding, small volume density, thermal conductivity both, thermal insulation, sound absorption performance is good, corrosion resistance, chemical stability and so on.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.