The Ultimate 2026 Rock Wool Bible: Why It Beats Fiberglass Every Single Time [Full Comparison]

In the 2026 insulation market, rock wool dominates fiberglass in fire safety (2150°F limit), acoustic performance, and R-value consistency. While costing 20-50% more upfront, its longevity and moisture resistance offer superior ROI for homeowners.

- Key Takeaways: The 30-Second Summary

- What Is Rock Wool Insulation?

- Origins and Manufacturing

- Rock Wool vs Mineral Wool

- Rock Wool vs. Fiberglass: The Core Comparison

- 2026 Performance Comparison Table

- Thermal Performance (R-Value)

- The Safety Factor: Fire and Health

- Why It Matters

- Health & The "Itch" Factor

- Acoustic Performance: The Soundproofing King

- The Science of Silence

- Cost Analysis 2026: Is the Premium Worth It?

- The Numbers

- Expert Tips for Installation & Common Mistakes

- Mistake #1: Squeezing the Bats

- Mistake #2: The "Gap" Error

- Conclusion

- Frequently Asked Questions about Rock Wool

- 1. Is rock wool actually better than fiberglass for soundproofing?

- 2. How does rock wool compare to fiberglass in terms of fire safety?

- 3. Does rock wool lose its R-value if it gets wet?

- 4. Is rock wool more difficult to install than fiberglass?

- References

Key Takeaways: The 30-Second Summary

· Fire Safety: Rock wool withstands temperatures up to 2,150°F, acting as a fire barrier, while fiberglass melts around 1,100°F.

· Acoustic Control: Due to higher density, rock wool reduces sound transmission significantly better (STC ~45) than standard fiberglass (STC ~39).

· ROI: Although material costs for rock wool are higher ($1.50–$2.50/sq. ft.), it provides long-term savings through durability and moisture resistance.

What Is Rock Wool Insulation?

Rock wool, also known as mineral wool or stone wool, is a fibrous insulation material produced by spinning molten rock (typically basalt) and recycled slag into fine fibers. It is renowned for its exceptional thermal insulation, sound absorption, and fire-resistant properties.

For a deeper dive into the technical specifications, check out our Definition for Rock Wool.

Origins and Manufacturing

Unlike fiberglass, which is spun from glass cullet and sand, what is rock wool made of? It is literally liquid stone. The manufacturing process mimics a volcano: volcanic rock is heated to approximately 3,000°F until it melts, then spun at high speeds into fibers. This creates a material that is:

· Denser: Roughly 3x heavier than fiberglass.

· Non-combustible: It does not burn.

· Hydrophobic: It repels water rather than soaking it up.

Rock Wool vs Mineral Wool

Many people ask about rock wool vs mineral wool. Technically, they are often used interchangeably in the US market. However, "mineral wool" is the umbrella term that can include both slag wool (industrial waste) and rock wool (natural stone). In 2026, premium brands focus strictly on stone-based rock wool batting for superior performance.

Rock Wool vs. Fiberglass: The Core Comparison

Rock wool insulation vs fiberglass is the most common debate in home construction. Rock wool consistently outperforms fiberglass in durability and safety, while fiberglass remains the budget option.

2026 Performance Comparison Table

|

Feature |

Rock Wool (Stone Wool) |

Fiberglass (Glass Wool) |

|

R-Value per Inch |

3.0 – 3.3 (Consistent) |

2.2 – 2.7 (Subject to compression) |

|

Fire Resistance |

Non-combustible (up to 2,150°F) |

Melts at ~1,100°F |

|

Moisture Handling |

Hydrophobic (Repels water) |

Absorbs water (can mold/sag) |

|

Soundproofing |

Excellent (High Density) |

Moderate (Low Density) |

|

Lifespan |

50+ Years (No sagging) |

15–25 Years (Prone to sagging) |

|

Cost (Installed) |

$1.50–$2.50 / sq. ft. |

$0.60 – $1.20 / sq. ft. |

Thermal Performance (R-Value)

The rock wool r value is not just higher on paper; it is more stable. Fiberglass relies on fluffiness (trapped air) to insulate. If you compress a 6-inch fiberglass batt into a 4-inch wall cavity, it loses significant R-value. Rock wool board and batts are rigid enough to resist compression, maintaining their R-3.0+ per inch rating for decades.

The Safety Factor: Fire and Health

Rock wool acts as a passive fire protection barrier because it is non-combustible and can withstand temperatures exceeding 2,000°F without melting.

Why It Matters

In my experience inspecting post-fire renovations, rock wool panels often remain intact while the surrounding wood framing has charred.

· Fire Blocking: It effectively stops flames from spreading through stud bays.

· Applications: This makes it the only safe choice for high-heat areas. Using rock wool for gas fireplace inserts or chimney surrounds is standard practice because fiberglass would simply melt away.

Health & The "Itch" Factor

Is rock wool insulation asbestos? No. Modern rock wool is bio-soluble, meaning if fibers are inhaled, the body can dissolve and clear them. However, it still requires safety gear.

· Dust: Rock wool is dustier than fiberglass.

· Skin Irritation: While the fibers are thicker and less sharp than glass shards, they can still irritate skin. Always wear long sleeves and gloves.

Acoustic Performance: The Soundproofing King

Rock wool acts as a dense mass barrier that dampens sound vibrations significantly better than the lighter fiberglass alternatives.

The Science of Silence

When you install rock wool batting in interior walls (Safe'n'Sound), you are increasing the wall's STC (Sound Transmission Class).

1. Mass: Rock wool is approx. 2.5 lbs/cu ft vs fiberglass at 0.5 lbs/cu ft.

2. Absorption: It absorbs low-frequency bass notes that easily pass through pink insulation.

3. Real-World Use: For home theaters, bedrooms, or offices, rock wool is the undisputed king.

Cost Analysis 2026: Is the Premium Worth It?

Current market data from 2025-2026 indicates that rock wool commands a 30-50% price premium over fiberglass.

The Numbers

· Material Cost: A bag of rock wool covering ~60 sq. ft. costs approx. $60-$80. Comparable fiberglass costs ~$35-$50.

· Long-Term ROI: According to reports from Market Research Future (2024), the global shift toward energy-efficient materials is driven by the realization that rock wool does not settle. Fiberglass can sag over 10-15 years, creating "phantom gaps" in your walls where heat escapes. Rock wool stays friction-fitted forever.

If you are looking for specific product recommendations, read our guide on the Top 10 Rock Wool Panel Brands to find the best value for your money.

Expert Tips for Installation & Common Mistakes

Installing rock wool is different from fiberglass. It behaves more like bread than cotton candy.

Mistake #1: Squeezing the Bats

Never compress insulation. While rock wool is dense, jamming it into a space too small will reduce its rock wool r value. It needs to sit naturally.

Mistake #2: The "Gap" Error

Because rock wool is rigid, it doesn't fluff out to fill corners like fiberglass. You must cut it accurately.

· Expert Tip: Use a serrated bread knife (long blade). Do not use a utility knife (box cutter); it will dull instantly on the stone fibers.

· Friction Fit: Cut the batt roughly 1/4 inch wider than the stud bay. It should slide in and hold itself up without staples.

Conclusion

When comparing rock wool vs fiberglass, the winner for performance is clear. While fiberglass saves money upfront, rock wool provides superior fire safety, soundproofing, and moisture resistance. In 2026, as building codes become stricter regarding energy efficiency and fire safety, rock wool is the future-proof investment for any serious renovation.

Here are 4 strategically crafted FAQs for your blog post, "The Ultimate 2026 Rock Wool Bible," designed to target the primary keyword rock wool while addressing the specific pain points of users comparing it to fiberglass.

Frequently Asked Questions about Rock Wool

1. Is rock wool actually better than fiberglass for soundproofing?

Absolutely. While fiberglass can dampen some sound, rock wool is significantly denser, which allows it to trap and dissipate sound waves much more effectively. Because it has a higher mass, it is the preferred choice for 2026 home theaters, recording studios, and multi-family units where reducing noise transfer between rooms is a priority.

2. How does rock wool compare to fiberglass in terms of fire safety?

There is no contest. Fiberglass can melt and smolder at relatively low temperatures, but rock wool is made from volcanic rock and slag, making it naturally non-combustible. It can typically withstand temperatures exceeding 1,175°C (2,150°F). In the event of a fire, rock wool acts as a fire barrier, slowing the spread of flames and providing crucial extra minutes for evacuation.

3. Does rock wool lose its R-value if it gets wet?

One of the biggest advantages of rock wool over fiberglass is its hydrophobic nature. Fiberglass acts like a sponge, losing its insulating R-value and sagging when damp. In contrast, rock wool is water-repellent; it does not absorb moisture, does not sag, and maintains its R-value even in humid conditions. This also makes it highly resistant to rot, mold, and mildew.

4. Is rock wool more difficult to install than fiberglass?

While rock wool is heavier, many DIYers and professionals find it easier to work with because of its "friction fit." Rock wool batts are rigid and can be cut precisely with a serrated knife to fit snugly between studs without the need for staples or wire. Unlike fiberglass, it won't slump over time, ensuring there are no gaps in your insulation envelope where heat could escape.

References

Sound Insulation Foam vs. Acoustic Panels: Which One Actually Stops Noise? (2026 Guide)

7 Dangerous Mistakes to Avoid When Selecting insulating materials for Your Car (2026 Guide)

Polyurethane Foam 2026: Guide to HFO Compliance & Performance

Why Glass Wool is the Secret to a 40% Lower Energy Bill: An Expert Deep Dive

service

Are your rubber foam products environmentally friendly?

Yes, our insulation products are designed with sustainability in mind. They help reduce energy consumption by minimizing heat loss and gain, and they are made from durable materials that have a long life cycle, reducing the need for frequent replacement.

FAQ

How do I choose the right insulation for my project?

Our team can help you choose the best material for heat insulation based on your specific needs, such as thermal resistance, acoustic properties, and environmental conditions.

Can your insulation products be customized?

Yes, we offer customized solutions for insulation material wholesale to meet the specifications of your project, including custom specifications, sizes, foils and adhesives, colors, etc.

What is the typical delivery time for custom orders?

Our daily production capacity is 800 cubic meters. Delivery time varies depending on the complexity of the insulation material wholesale order, but we can deliver large quantities of customized products within 4-6 weeks after the approval date, and small quantities can be delivered within 15 days.

You might also like

138°High-temperature universal adhesive

This product has passed the EU REACH non-toxic standard and ROHS non-toxic standard. (This product is a yellow liquid).

Anggu 138°high temperature universal glue is a high-end product, with high viscosity, slow drying, curing of the adhesive layer, and a maximum resistance to continuous temperature of 138℃.

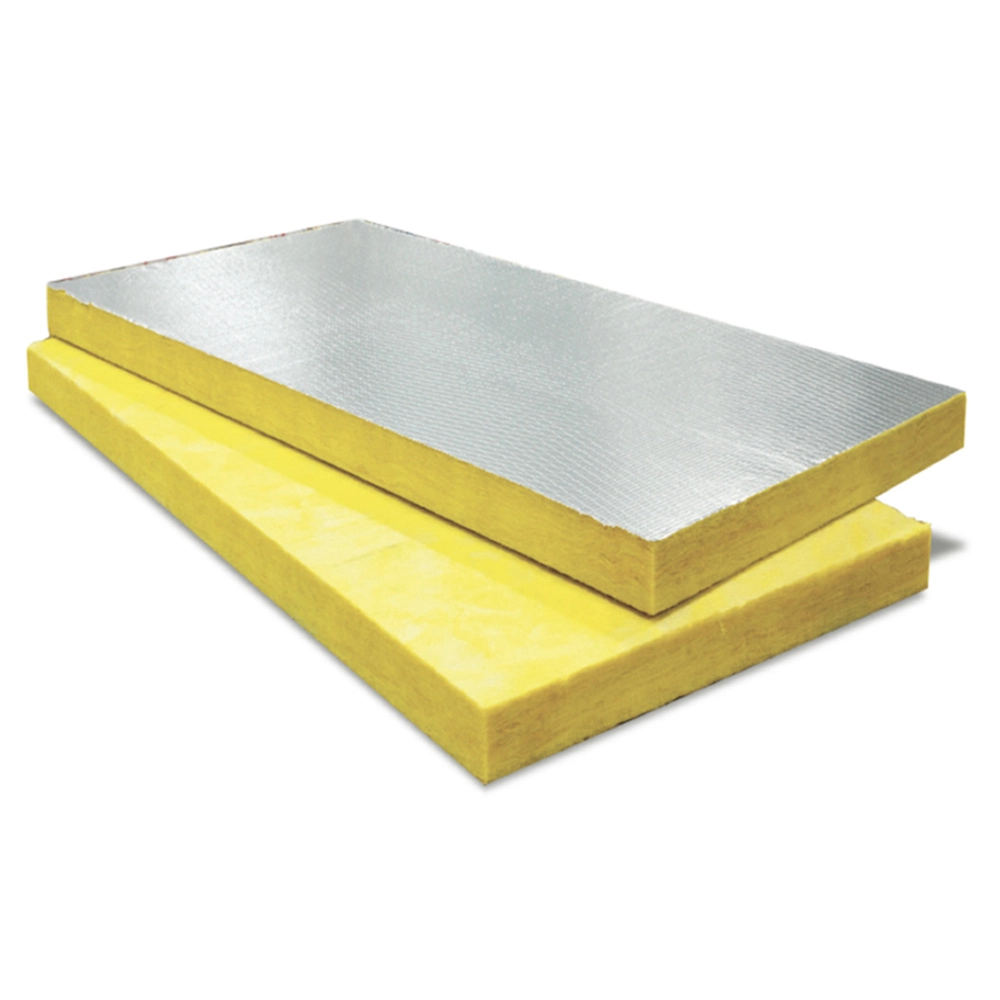

Wholesale Roof And Wall Thermal Heat Insulation 50mm Thickness Aluminum Foil Fiberglass Insulation Panel Board Glass Wool Price

Glass wool is the molten glass fiber, the formation of cotton-like material, chemical composition belongs to the glass category, is a kind of inorganic fiber. With good molding, small volume density, thermal conductivity both, thermal insulation, sound absorption performance is good, corrosion resistance, chemical stability and so on.

Environmentally friendly self spraying adhesive

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. This product is a yellow liquid.

Anggu spray glue is a product with high cost performance and a wide application range. It is mainly used for home construction, engineering construction, and various construction defect repair places. This product is low odor, no formaldehyde, spray-convenient glue, table drying speed, long bonding time, no chalking.

Special adhesive for insulation nail

This product has passed the EU REACH non-toxic standard and ROHS non-toxic standard. (This product is a yellow liquid).

Anggu insulation nail special adhesive is a adhesive with high viscosity, slow drying, aging resistance, high strength, and excellent brushing performance; The special adhesive for insulation nails has a slow drying speed and strong adhesion to the iron sheet. It can be flexibly moved during construction, and has a strong bonding force after curing, low odor.and is non-toxic.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.