FUNAS Glass Wool Insulation – High Quality Glass Wool Process

Product Overview

FUNAS glass wool insulation is a high-performance thermal and acoustic material made through a controlled glass wool manufacturing process. Since 2011, FUNAS has combined research, production and service to deliver durable insulation solutions for industries like petrochemical, power, metallurgy, polysilicon, central air conditioning and refrigeration. Our Guangzhou hub includes a 10,000 m² storage center to ensure timely supply.

Glass Wool Manufacturing Process

1. Raw Materials

High-quality silica sand, recycled glass and flux materials are selected to ensure a stable melt and consistent fiber quality.

2. Melting & Fiberizing

Materials are melted at high temperature to form molten glass. The molten glass is then fiberized using controlled spinning or flame techniques to create fine, uniform fibers that trap air and provide insulation.

3. Binder Application

A specially formulated binder is applied to the fibers to give the mat structure and resilience. The binder is chosen for low smoke, low odor and long-term stability.

4. Curing & Cutting

The fiber mat passes through curing ovens to set the binder. After curing, the glass wool is cut and shaped into boards, rolls or loose-fill forms according to customer needs.

5. Quality Control & Packaging

Strict inspections check density, thermal conductivity, dimensions and fire performance. Products are then packed to protect against moisture and contamination during transport and storage.

Key Features & Benefits

- Excellent thermal and acoustic insulation

- Lightweight and easy to install

- Non-combustible glass-based fibers

- Stable long-term performance

- Available in rolls, boards, and loose-fill

Applications & Customization

Widely used in petroleum, petrochemical, power plants, metallurgical plants, polysilicon production, coal chemical industry, HVAC systems and refrigeration. FUNAS offers brand customization to meet specific project needs.

Certifications & Why Choose FUNAS

FUNAS has obtained CCC, CQC, CE, ROHS, CPR, UL and FM certifications and holds ISO 9001 and ISO 14001 systems. Our products are engineered, manufactured and tested to provide reliable, compliant insulation. Choose FUNAS for proven quality, expert support and global vision.

Visit https://www.funasinsulations.com/ for technical datasheets and contact information.

Our Advantages

Strict quality assurance

Our best materials for insulation for heat have passed multiple international certifications, such as ISO/CE/UL, and each process has undergone strict quality inspection to ensure that every product is of high quality.

Personalized solutions

By deeply understanding our customers' needs, we provide personalized hot and cold insulation material solutions to ensure that the building material selected meets our customers' unique business requirements.

Brand advantage

We are an experienced rubber foam insulation company built on excellent brands. In the market, we are known for innovation, quality and credibility, providing customers with building material they can trust.

Product customization capabilities

The difference between us and our competitors lies in our heat resistant insulation material product customization capabilities, covering size, specifications, color, packaging and other aspects to meet customers' personalized needs.

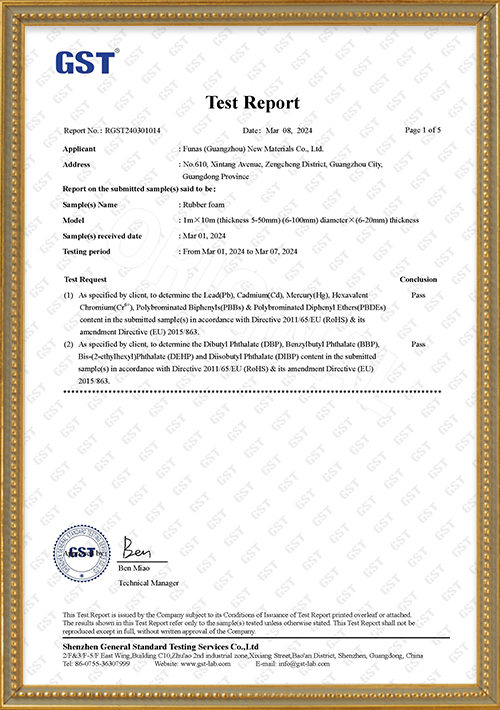

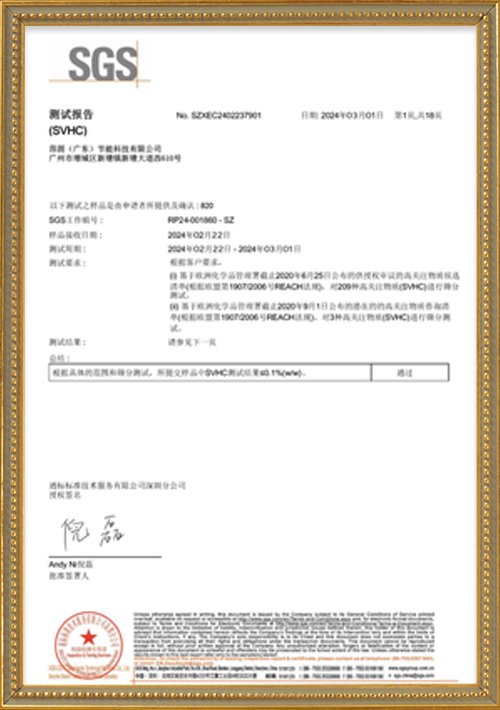

Certificate display

Rubber and plastic CE test report

CE-CPR(rubber foam)

SGS

Frequently Asked Questions

What types of rubber foam insulation do you offer?

We offer a wide range of rubber foam insulation with different thicknesses and specifications. Thermal insulation material manufacturer FUNAS sleeves and sheets are suitable for different application scenarios.

How does your technical support work?

Our technical support team is available to guide you through every stage of your project—from product selection and design to installation. We provide expert consultation to ensure that you get the best insulation solution for your needs and can assist with troubleshooting if needed.

What types of rubber foam insulation products do you offer?

We offer a wide range of rubber foam insulation products, including custom shapes and sizes, thermal and acoustic insulation solutions, and options with specialized coatings such as flame retardancy and water resistance. Our products are suitable for applications in HVAC, automotive, construction, and more.

Can your insulation products be customized?

Yes, we offer customized solutions for insulation material wholesale to meet the specifications of your project, including custom specifications, sizes, foils and adhesives, colors, etc.

Wholesale Perfect Fire Resistant Performance High Strength Acoustic Mineral Wool Insulation Rock Wool Board Panel Plain Slab

Rock wool board, that is, a kind of exterior insulation material. When the market share of 90% of the organic thermal insulation materials in the stagnant wait-and-see, as a fire rating of A-class exterior insulation inorganic material rock wool, has ushered in an unprecedented market opportunity.

Wholesale Rock Wool Mineral Wool Roll Blanket

Durable rock wool roll with outstanding fire resistance and insulation properties. Ideal for industrial and construction applications.

Wholesale Perfect Fire Resistant Performance High Strength Acoustic Mineral Wool Insulation Rock Wool Roll Panel Plain Slab

Rock wool, that is, a kind of exterior insulation material. When the market share of 90% of the organic thermal insulation materials in the stagnant wait-and-see, as a fire rating of A- class exterior insulation inorganic material rock wool has ushered in an unprecedented market opportunity.

Wholesale High-Density Acoustic Foam Sound-absorbing Sponge Soundproof Cotton

Enhance sound clarity and reduce noise with FUNAS Wholesale High-Density Acoustic Foam Sound-absorbing Sponge. Polyurethane sponge is a low density PU with foam density less than 18 kg/m3. This premium soundproof cotton delivers superior sound absorption, perfect for studios, offices, and home theaters. Optimize your acoustic environment now!