Understanding the Polyurethane Foam Manufacturing Process: A Step-by-Step Guide

Explore the polyurethane foam manufacturing process with FUNAS' comprehensive step-by-step guide. Delve into the intricacies of producing versatile, high-quality foam materials used across industries. Gain insights into efficient practices and advanced techniques that define our commitment to excellence and sustainability. Discover how FUNAS leads the way in innovative foam solutions, tailored to meet diverse application needs.

- Preface

- What is Polyurethane Foam?

- Step-by-Step Polyurethane Foam Manufacturing Process

- Raw Materials Used in Polyurethane Foam Production

- Mixing and Reaction of Chemicals

- Expanding Foam

- Curing and Molding the Foam

- Final Product and Quality Control

- Different Types of Polyurethane Foam

- How to Choose Polyurethane Foam for Different Needs?

- FUNAS Insulation: Leading Polyurethane Foam Manufacturer in China

- Conclusion

- FAQs about the Foam Manufacturing Process

Preface

What is Polyurethane Foam?

Step-by-Step Polyurethane Foam Manufacturing Process

Raw Materials Used in Polyurethane Foam Production

Mixing and Reaction of Chemicals

Expanding Foam

Curing and Molding the Foam

Final Product and Quality Control

Different Types of Polyurethane Foam

| Type of Foam | Characteristics | Applications |

| Flexible Foam | Soft, flexible, low-density foam. | Upholstery, mattresses, packaging, automotive seat cushions. |

| Rigid Foam | High-density, sturdy, excellent insulation. | Insulation in buildings, refrigeration units, pipe insulation, automotive parts. |

| Semi-Rigid Foam | Offers a balance between flexibility and rigidity. | Insulation in automotive parts, gaskets, seals. |

|

Spray Foam |

Applied as a liquid, expands into foam. |

Building insulation, roofing, air-sealing. |

| High Resilience Foam | High elasticity, quick recovery. | High-end mattresses, seat cushions, medical cushions. |

How to Choose Polyurethane Foam for Different Needs?

-

Density: affects the strength and durability of the foam. Higher-density foams are more rigid and durable, making them suitable for insulation or structural applications, while lower-density foams are better for cushioning or flexible uses.

-

Flexibility: defines the ability of the foam to bear pressure and regain its shape. Conventional flexible foams have relatively high elasticity and are suitable for cushioning applications such as furniture and automobile seats.

-

Thermal Insulation Properties: Especially important for uses where it is necessary to save energy, for example in construction, insulation, or refrigeration equipment. Low thermal conductivity rigid foam is suitable for these uses.

-

Acoustic Performance: Of particular relevance to soundproofing functions. The foams with small and closely packed cells have good sound absorption characteristics and are therefore suitable for use in walls, floors, and other sound-vulnerable applications.

-

Customization Requirements: There are also some applications where foam will have specific surface treatment (e.g., fire-resistant or water-proof). One should then ask whether these additional features are needed depending on the conditions where the foam is going to be used.

-

FUNAS Insulation: Leading Polyurethane Foam Manufacturer in China

Conclusion

FAQs about the Foam Manufacturing Process

7 Dangerous Mistakes to Avoid When Selecting insulating materials for Your Car (2026 Guide)

Polyurethane Foam 2026: Guide to HFO Compliance & Performance

The Ultimate 2026 Rock Wool Bible: Why It Beats Fiberglass Every Single Time [Full Comparison]

Why Glass Wool is the Secret to a 40% Lower Energy Bill: An Expert Deep Dive

FAQ

How do I choose the right insulation for my project?

Our team can help you choose the best material for heat insulation based on your specific needs, such as thermal resistance, acoustic properties, and environmental conditions.

What types of rubber foam insulation do you offer?

We offer a wide range of rubber foam insulation with different thicknesses and specifications. Thermal insulation material manufacturer FUNAS sleeves and sheets are suitable for different application scenarios.

service

What types of rubber foam insulation products do you offer?

We offer a wide range of rubber foam insulation products, including custom shapes and sizes, thermal and acoustic insulation solutions, and options with specialized coatings such as flame retardancy and water resistance. Our products are suitable for applications in HVAC, automotive, construction, and more.

What is your shipping and delivery process like?

We offer reliable logistics services for insulation material wholesale, both domestically and internationally. Our team ensures secure packaging, timely shipping, and real-time tracking so that your order reaches you in perfect condition and on schedule.

You might also like

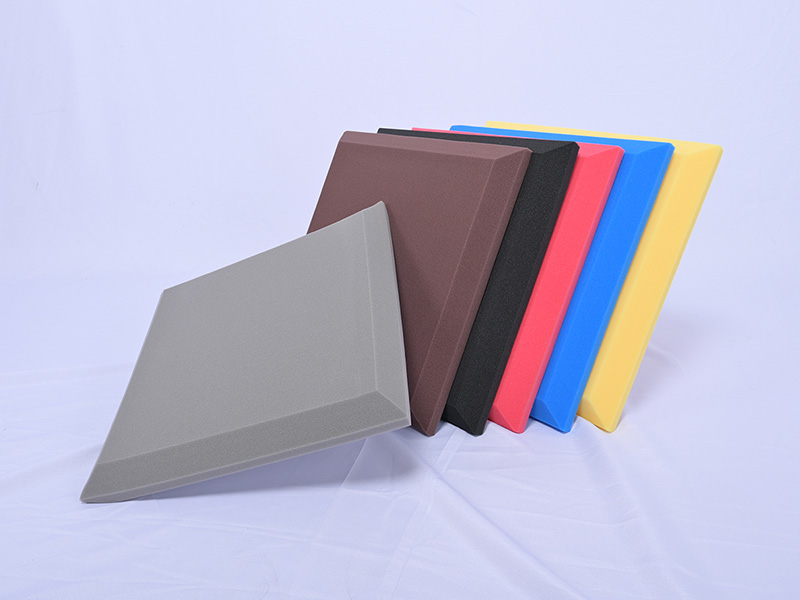

Wholesale High-Density Acoustic Foam Sound-absorbing Sponge Soundproof Cotton

Enhance sound clarity and reduce noise with FUNAS Wholesale High-Density Acoustic Foam Sound-absorbing Sponge. Polyurethane sponge is a low density PU with foam density less than 18 kg/m3. This premium soundproof cotton delivers superior sound absorption, perfect for studios, offices, and home theaters. Optimize your acoustic environment now!

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.