Top 10 Global Polyurethane Foam Manufacturers for 2026

A comprehensive guide to the global polyurethane foam industry for 2026. This article covers essential definitions, foam types (rigid vs. flexible), manufacturing processes, and future sustainability trends. It features a ranked list of the top 10 manufacturers, including industry leaders and rising stars, alongside expert advice on selection and safety.

- What is Polyurethane Foam?

- Key Characteristics

- Key Takeaways: Polyurethane Foam at a Glance

- The Science Behind the Foam: How Polyurethane is Made

- The Manufacturing Process

- Understanding the Diverse Types of Polyurethane Foam

- Flexible Polyurethane Foam

- Rigid Polyurethane Foam

- Semi-Rigid Polyurethane Foam

- Open-Cell vs. Closed-Cell Polyurethane Foam

- Specialized PU Foam Types

- Unpacking the Benefits of Polyurethane Foam

- Where Polyurethane Foam Excels: Comprehensive Applications

- Choosing the Right Polyurethane Foam: Expert Tips & Common Mistakes

- Expert Tips

- Common Mistakes

- Sustainability & Innovations: The Future of Polyurethane Foam (2026 & Beyond)

- Polyurethane Foam vs. Alternatives: A Comparative Look

- Viscoelastic Foams vs Polyurethane Foam

- Expanded Polystyrene (EPS)

- Mineral Wool

- Top 10 Global Polyurethane Foam Manufacturers

- 1. BASF (Germany)

- 2. FUNAS (Global)

- 3. Carpenter Co. (USA)

- 4. Covestro (Germany)

- 5. Huntsman Corporation (USA)

- 6. Saint-Gobain (France)

- 7. The Woodbridge Group (Canada)

- 8. Sekisui Chemical (Japan)

- 9. Dow (USA)

- 10. Rogers Corporation (USA)

- Conclusion

- FAQ

- Is polyurethane foam toxic?

- Is polyurethane foam safe to use in homes?

- What is the difference between expanding foam and foam board?

- Can polyurethane foam be recycled?

- References

What is Polyurethane Foam?

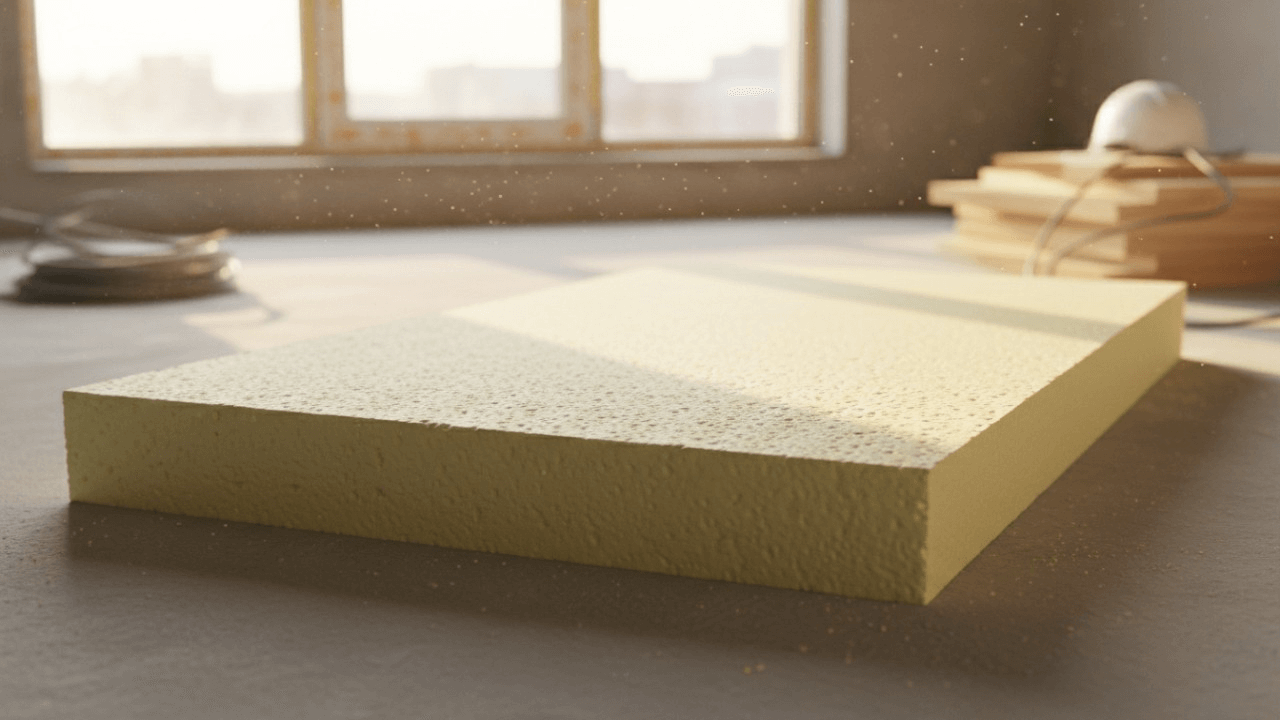

Polyurethane foam is a versatile polymer material created by reacting polyols and isocyanates, widely used for insulation, cushioning, and structural support. It creates a cellular structure that can be engineered to be either flexible, like in mattresses, or rigid, like in building insulation.

Once the chemical reaction occurs, the material expands to fill spaces, making polyurethane expanding foam a critical solution for sealing gaps and providing thermal resistance. Its adaptability allows it to serve industries ranging from automotive to construction.

Key Characteristics

· Versatility: Can be molded into polyurethane foam sheets, boards, or applied as a spray.

· Structure: Available in open-cell (breathable, soft) and closed-cell (dense, moisture-resistant) forms.

· Durability: Resistant to mold, mildew, and many chemicals.

Key Takeaways: Polyurethane Foam at a Glance

· Versatile Material: Polyurethane foam is a highly customizable polymer suitable for insulation, cushioning, and sealing.

· Two Main Categories: It exists primarily as flexible polyurethane foam (comfort) and rigid polyurethane foam (insulation).

· Industry Staple: Used extensively in construction, automotive, furniture, and packaging sectors.

· Performance: Offers superior thermal insulation, sound dampening, and a high strength-to-weight ratio.

· Future Outlook: Innovations for 2026 are driving towards bio-based materials and enhanced recycling methods.

The Science Behind the Foam: How Polyurethane is Made

Polyurethane foam is produced through a polymerization process where a polyol (an alcohol with multiple hydroxyl groups) reacts with a diisocyanate in the presence of blowing agents and catalysts. This reaction creates the polymer matrix and the gas bubbles that form the cellular foam structure.

The Manufacturing Process

1. Raw Materials: The primary components are polyols and isocyanates (MDI or TDI).

2. Mixing: ingredients are precisely metered and mixed at high speeds.

3. Expansion: The reaction generates heat and gas, causing the mixture to rise and cure into foam polyurethane.

4. Curing & Cutting: The foam acts as a solid block (slabstock) or molded part, which is then cured and cut into products like a polyurethane foam sheet.

For a deeper dive into the technical steps, read our guide on the polyurethane foam manufacturing process.

Understanding the Diverse Types of Polyurethane Foam

Flexible Polyurethane Foam

Flexible polyurethane foam is an open-cell porous material known for its resilience and comfort. It allows air to pass through, preventing heat buildup in cushioning applications.

· Common Uses: Mattresses, sofa cushions, automotive seating, and sponges.

Rigid Polyurethane Foam

Rigid polyurethane foam is a dense, closed-cell material that offers high structural strength and exceptional thermal resistance. It is the gold standard for energy-efficient insulation.

· Common Uses: Polyurethane foam insulation in walls/roofs, refrigeration panels, and polyurethane foam board.

Semi-Rigid Polyurethane Foam

This type bridges the gap between flexible and rigid, offering shock absorption and dampening properties.

· Common Uses: Car bumpers, dashboard panels, and protective packaging.

Open-Cell vs. Closed-Cell Polyurethane Foam

· Open-Cell: Soft and "spongy" with interconnected cells. Excellent for soundproofing but not water-resistant.

· Closed-Cell: Rigid and dense with sealed cells. Acts as a vapor barrier, provides structural integrity, and offers higher R-values per inch.

Specialized PU Foam Types

· High Density Polyurethane Foam: Engineered for heavy-load bearing capabilities, used in commercial seating and industrial packaging.

· Rebond Foam: Made from shredded scrap foam, commonly used in carpet underlayment.

· Spray Foam: Applied as a liquid that expands 30-60 times its volume to seal cracks and voids.

Unpacking the Benefits of Polyurethane Foam

· Thermal Efficiency: Polyurethane foam insulation offers one of the highest R-values of any insulation material, significantly reducing energy costs.

· Acoustic Control: Open-cell varieties effectively absorb sound waves, reducing noise pollution.

· Lightweight Strength: Provides structural support without adding significant weight, crucial for automotive fuel efficiency.

· Versatility: Available in various forms, including polyurethane foam sheets and expanding sprays, to fit any project requirement.

· Moisture Resistance: Closed-cell foam acts as a barrier against moisture intrusion, preventing mold growth.

Where Polyurethane Foam Excels: Comprehensive Applications

· Construction: Polyurethane expanding foam seals air leaks, while rigid boards insulate roofs and walls.

· Automotive: Used for lightweighting vehicles, sound deadening, and comfortable seating.

· Furniture: The core component of modern mattresses and upholstered furniture.

· Packaging: Protects sensitive electronics and goods during shipping.

· Appliances: Essential for keeping refrigerators and freezers cold.

Choosing the Right Polyurethane Foam: Expert Tips & Common Mistakes

Selecting the correct polyurethane foam requires understanding your specific application needs regarding density, firmness, and environment.

Expert Tips

1. Check the Density: Higher density usually equates to longer lifespan and better durability.

2. Verify R-Value: For insulation, ensure the polyurethane foam insulation meets your local energy code requirements.

3. Safety First: Always ask, is polyurethane foam safe for your intended use? Ensure it is fully cured and, if necessary, covered with a thermal barrier.

Common Mistakes

· Ignoring UV Exposure: Polyurethane foam degrades in sunlight; it must be coated or covered if used outdoors.

· Wrong Cell Type: Using open-cell foam in a high-moisture area can lead to water retention issues.

· Poor Surface Prep: Expanding foam will not adhere correctly to dirty or oily surfaces.

Sustainability & Innovations: The Future of Polyurethane Foam (2026 & Beyond)

The industry is rapidly shifting towards a circular economy. By 2026, expect to see:

· Bio-Based Polyols: Replacing petrochemicals with plant-based oils (soy, castor) to reduce carbon footprint.

· Advanced Recycling: Chemical recycling technologies that break down polyurethane foam back into virgin-quality raw materials.

· Smart Foams: Materials with phase-change properties that actively regulate temperature.

Polyurethane Foam vs. Alternatives: A Comparative Look

Viscoelastic Foams vs Polyurethane Foam

Viscoelastic foam (Memory Foam) is a type of polyurethane with added chemicals to increase density and viscosity. While memory foam offers superior contouring and pressure relief, standard polyurethane foam provides a quicker response (bounce) and is generally more breathable and cost-effective.

Expanded Polystyrene (EPS)

EPS is cheaper but brittle and has a lower R-value per inch compared to rigid polyurethane foam. Polyurethane also provides a better air seal.

Mineral Wool

Mineral wool is fire-resistant and great for sound, but polyurethane foam insulation is superior for air sealing and moisture control in tight spaces.

Top 10 Global Polyurethane Foam Manufacturers

Below is the definitive list of the top manufacturers driving the industry in 2026. For a broader look at specific brands, check our guide on polyurethane foam insulation brands.

1. BASF (Germany)

BASF is a global chemical giant and a leader in polyurethane systems. Their portfolio includes the popular WALLTITE and ENERTITE spray foam lines. They are renowned for their heavy investment in R&D, focusing on energy-efficient and sustainable building solutions.

2. FUNAS (Global)

FUNAS has rapidly established itself as a premier global manufacturer of high-performance polyurethane foam. Known for bridging the gap between premium quality and cost-effectiveness, FUNAS specializes in both rigid and flexible foam solutions for construction and industrial applications. Their commitment to integrating bio-based materials and advanced manufacturing techniques places them at the forefront of the 2026 market.

3. Carpenter Co. (USA)

Carpenter Co. is the world's largest vertically integrated manufacturer of polyurethane foams. After acquiring Recticel's Engineered Foams division, they have solidified their dominance in flexible foams for bedding, furniture, and technical applications worldwide.

4. Covestro (Germany)

Formerly a part of Bayer, Covestro is a leading supplier of high-tech polymer materials. They are a major producer of the raw materials (polyols and isocyanates) used to make rigid polyurethane foam for insulation and refrigeration, driving innovation in circular economy practices.

5. Huntsman Corporation (USA)

Huntsman is a key player in the MDI-based polyurethane market. Their division, Huntsman Building Solutions, is a global leader in spray polyurethane foam (SPF) insulation, offering a wide range of open-cell and closed-cell products for residential and commercial use.

6. Saint-Gobain (France)

Saint-Gobain focuses on specialized engineered foams. Their Norseal brand is widely used for gasketing, sealing, and cushioning in industrial, automotive, and construction sectors, providing high-performance solutions for demanding environments.

7. The Woodbridge Group (Canada)

Woodbridge is a global leader in automotive foam solutions. They manufacture molded flexible polyurethane foam for car seating, headrests, and sound insulation components, partnering with major automotive OEMs to improve vehicle comfort and safety.

8. Sekisui Chemical (Japan)

Sekisui is a pioneer in high-performance foam technologies, particularly cross-linked polyolefin foams. Their Softlon and Volara brands are essential in industrial, medical, and automotive applications where superior chemical resistance and smooth aesthetics are required.

9. Dow (USA)

Dow is a massive supplier of polyurethane systems and raw materials. Their VORANOL polyols and PAPI isocyanates are industry benchmarks, enabling manufacturers worldwide to produce high-quality rigid and flexible polyurethane foams.

10. Rogers Corporation (USA)

Rogers Corporation specializes in high-performance engineered materials. Their PORON microcellular polyurethanes are the industry standard for shock absorption and sealing in electronics, automotive, and footwear, offering long-term reliability.

Conclusion

As we move into 2026, the polyurethane foam industry continues to evolve, driven by demands for better energy efficiency and sustainability. Whether you are looking for polyurethane foam sheets for packaging or high-performance polyurethane foam insulation for a building project, understanding the types and manufacturers is key to success. Companies like BASF and FUNAS are leading the charge, ensuring that this versatile material remains essential to modern manufacturing.

FAQ

Is polyurethane foam toxic?

Cured polyurethane foam is generally considered non-toxic and inert. However, during the application of spray foam, isocyanates are released, which can be harmful if inhaled. Proper ventilation and PPE are strictly required during installation. Once fully cured, it releases no fumes.

Is polyurethane foam safe to use in homes?

Yes, is polyurethane foam safe for homes? Absolutely, provided it is fully cured. It is a standard material in mattresses, sofas, and insulation. Building codes often require it to be covered by a thermal barrier (like drywall) to ensure fire safety.

What is the difference between expanding foam and foam board?

Polyurethane expanding foam comes in a can or spray rig and expands to fill irregular gaps, making it ideal for air sealing. Polyurethane foam board is a rigid, pre-formed panel used for continuous insulation on walls and roofs.

Can polyurethane foam be recycled?

Yes, predominantly through mechanical recycling (chopping it into rebond foam for carpet pads) or chemical recycling (breaking it down into raw polyols), which is becoming more scalable in 2026.

References

7 Dangerous Mistakes to Avoid When Selecting insulating materials for Your Car (2026 Guide)

Polyurethane Foam 2026: Guide to HFO Compliance & Performance

The Ultimate 2026 Rock Wool Bible: Why It Beats Fiberglass Every Single Time [Full Comparison]

Why Glass Wool is the Secret to a 40% Lower Energy Bill: An Expert Deep Dive

service

Can I request custom dimensions or properties for my insulation needs?

Yes, we specialize in custom solutions. Whether you need specific dimensions, thicknesses, densities, or additional coatings, we can work with you to manufacture insulation products tailored to your exact requirements of good materials for heat insulation.

What is your shipping and delivery process like?

We offer reliable logistics services for insulation material wholesale, both domestically and internationally. Our team ensures secure packaging, timely shipping, and real-time tracking so that your order reaches you in perfect condition and on schedule.

How does your technical support work?

Our technical support team is available to guide you through every stage of your project—from product selection and design to installation. We provide expert consultation to ensure that you get the best insulation solution for your needs and can assist with troubleshooting if needed.

FAQ

What types of rubber foam insulation do you offer?

We offer a wide range of rubber foam insulation with different thicknesses and specifications. Thermal insulation material manufacturer FUNAS sleeves and sheets are suitable for different application scenarios.

You might also like

820 Pipe special adhesive

This product has passed the EU REACH non-toxic standard, ROHS non-toxic standard. (The product is black glue.)

Anggu 820glue is a low-odor, high-strength quick-drying glue; Fast drying speed, long bonding time, no powder, non-toxic.

Blue Rubber-plastic Tube Rubber foam pipe wholesale

Environmentally friendly self spraying adhesive

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. This product is a yellow liquid.

Anggu spray glue is a product with high cost performance and a wide application range. It is mainly used for home construction, engineering construction, and various construction defect repair places. This product is low odor, no formaldehyde, spray-convenient glue, table drying speed, long bonding time, no chalking.

Wholesale black Rubber-plastic Board Rubber foam panel sheet

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.